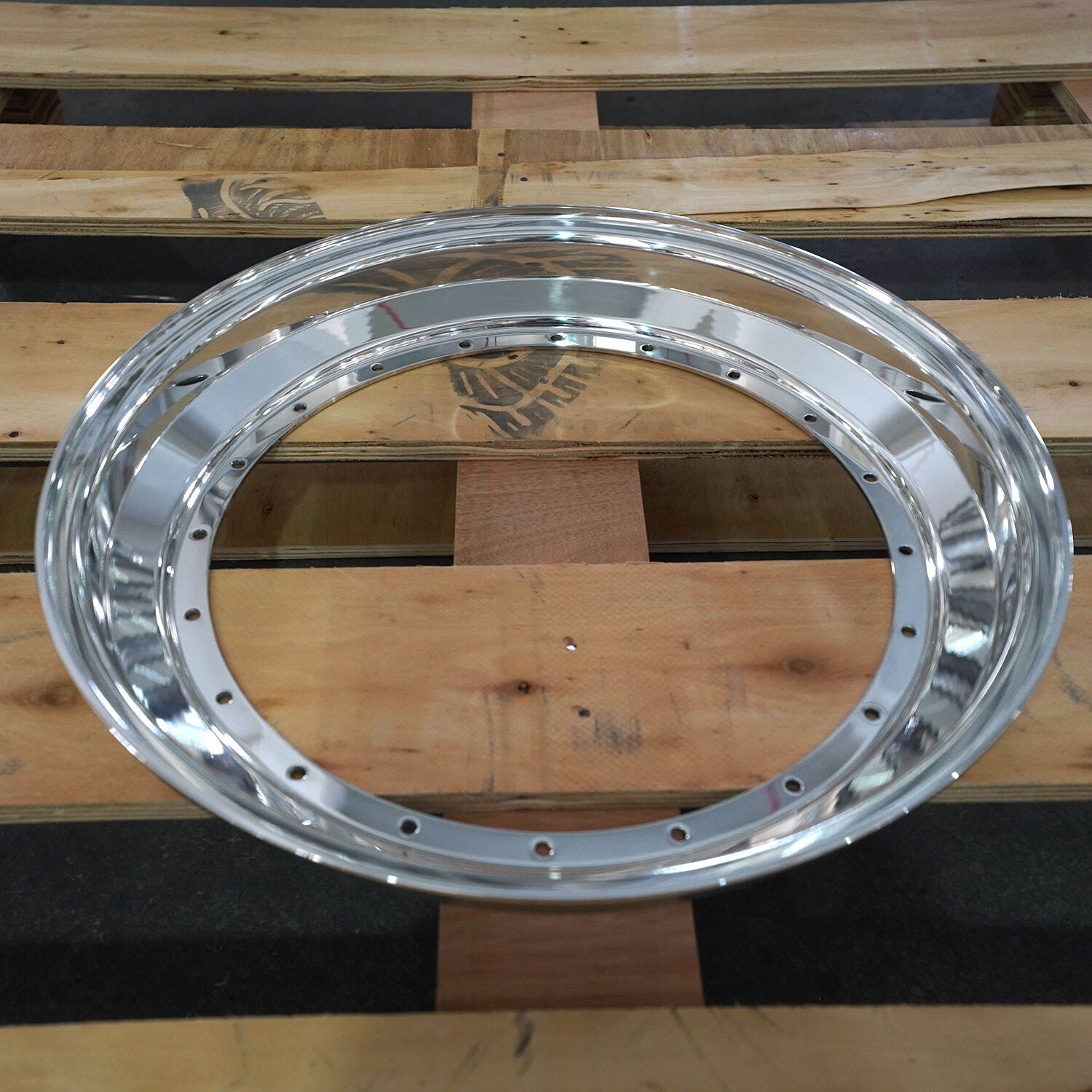

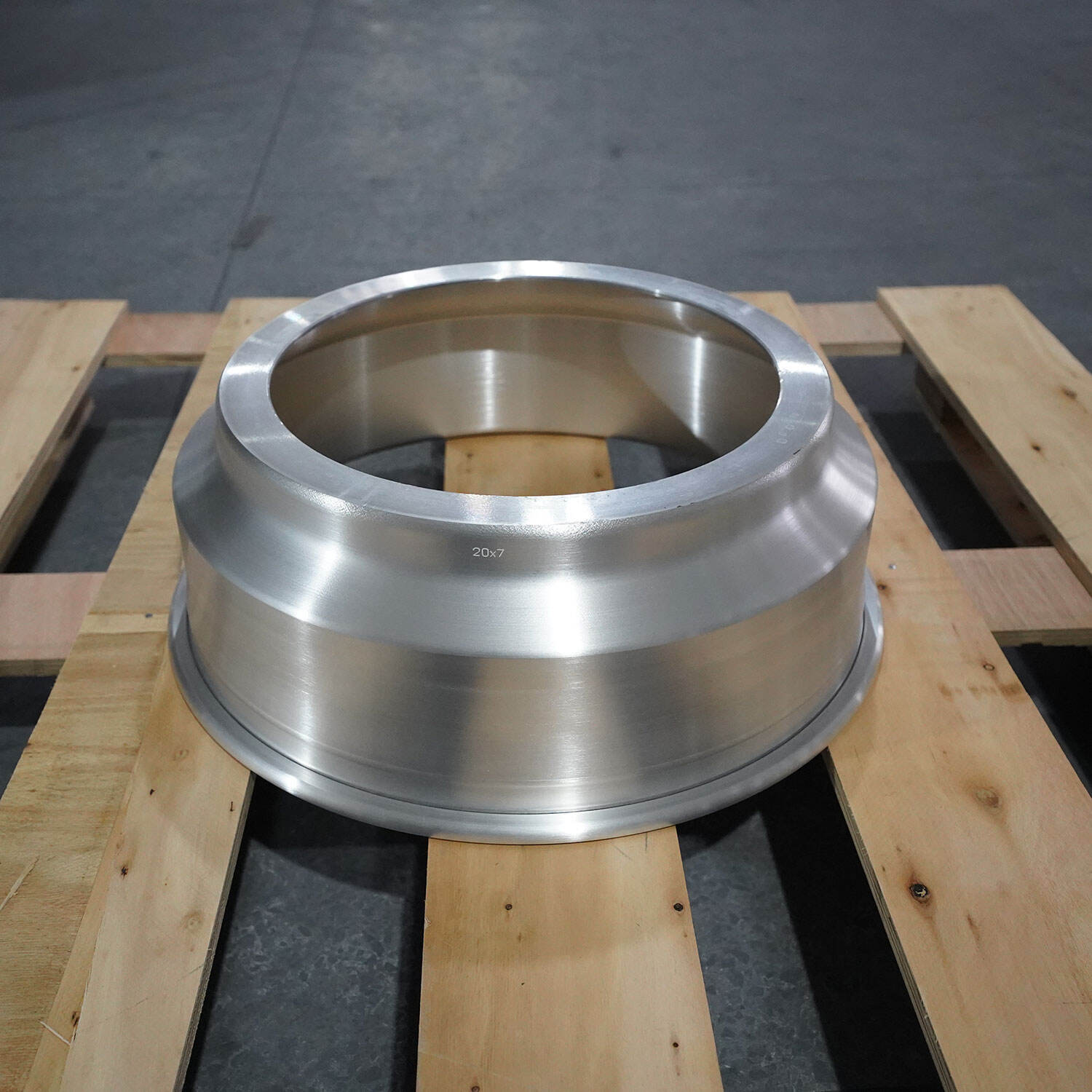

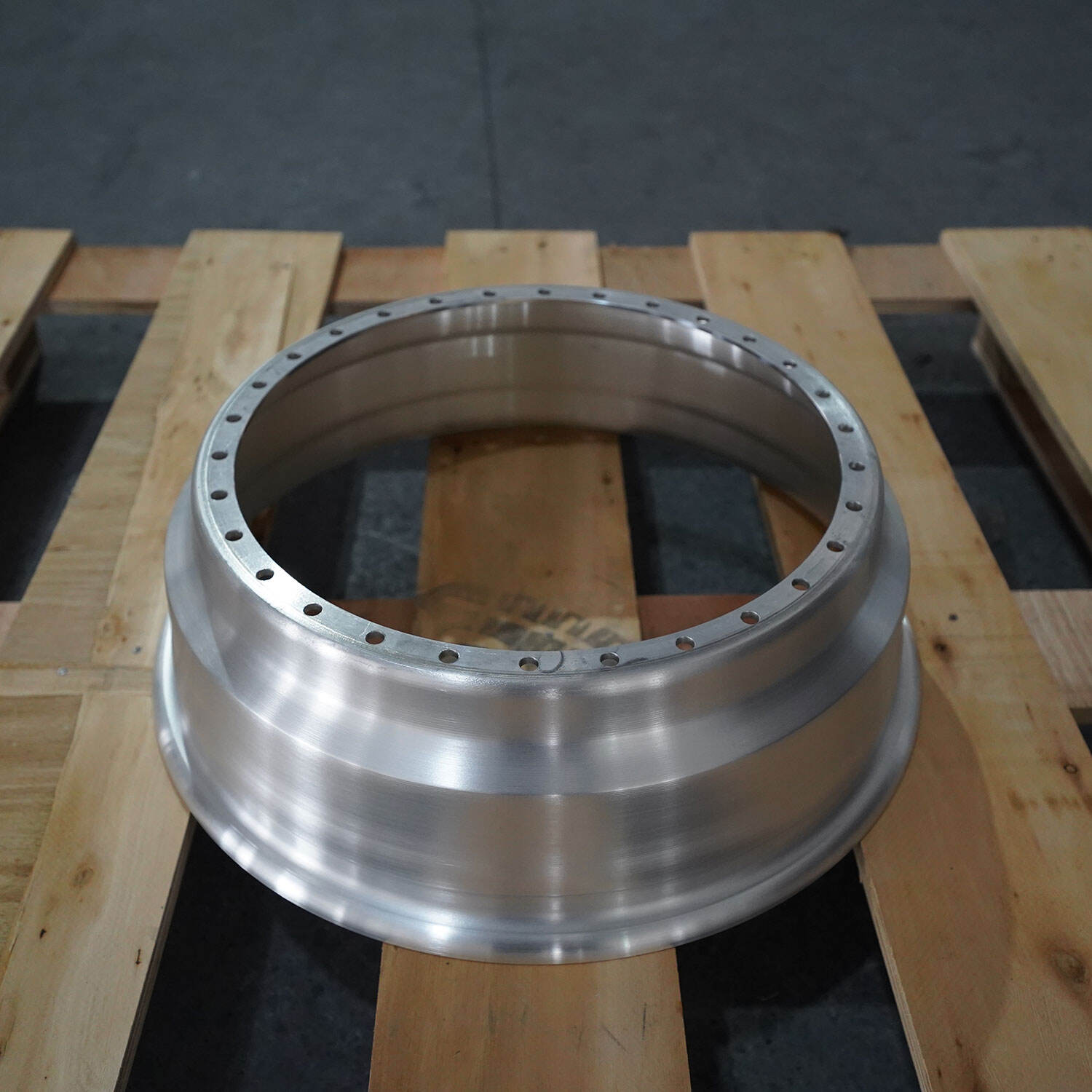

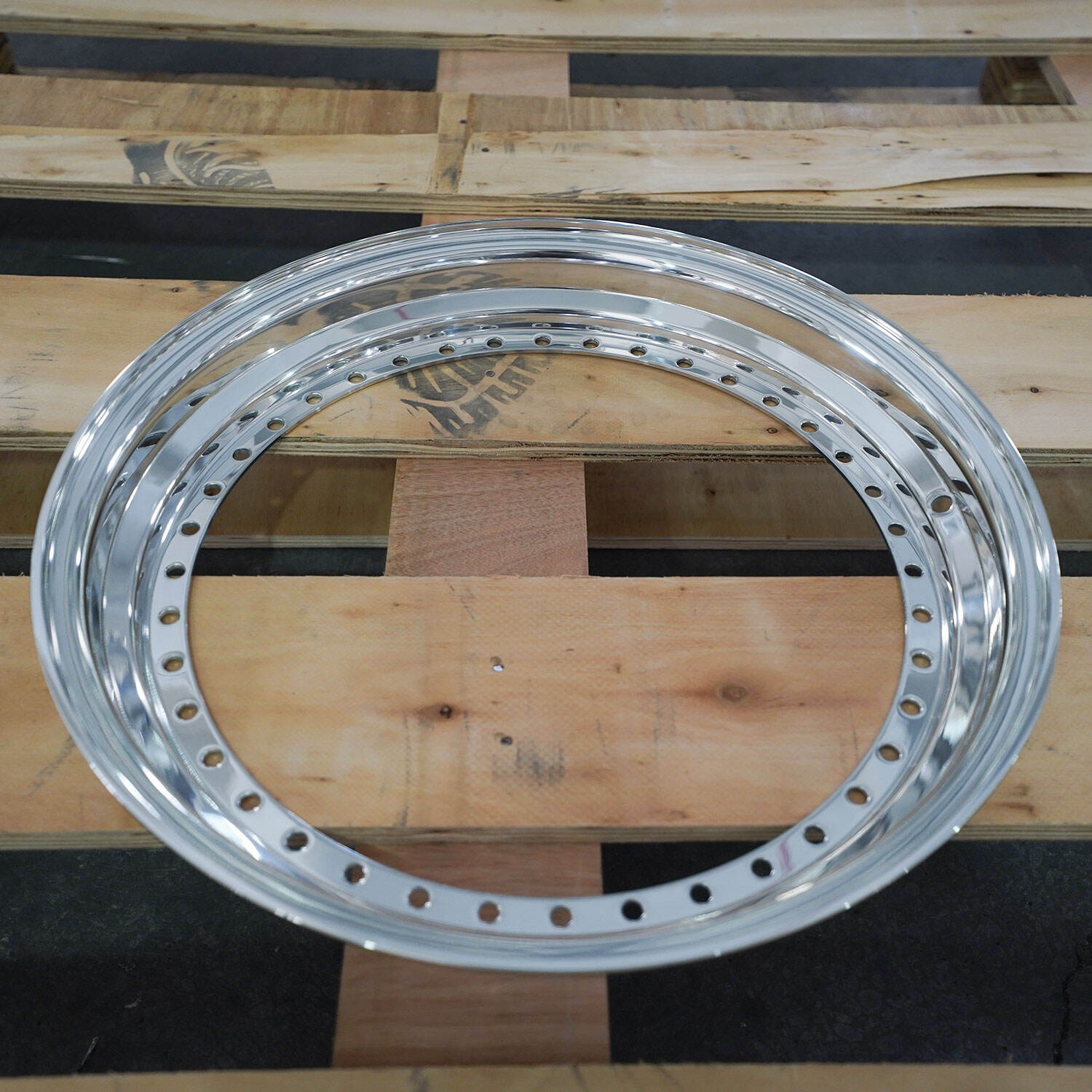

custom 6061 T6 aluminum alloy polished 19x2.5 step up lip for 3 piece forged wheel

Introduction

Introduction

| Place of Origin: | China |

| Brand Name: | PWC |

| Model Number: | 19*2.5 inch |

| Certification: | ISO9001 |

Description:

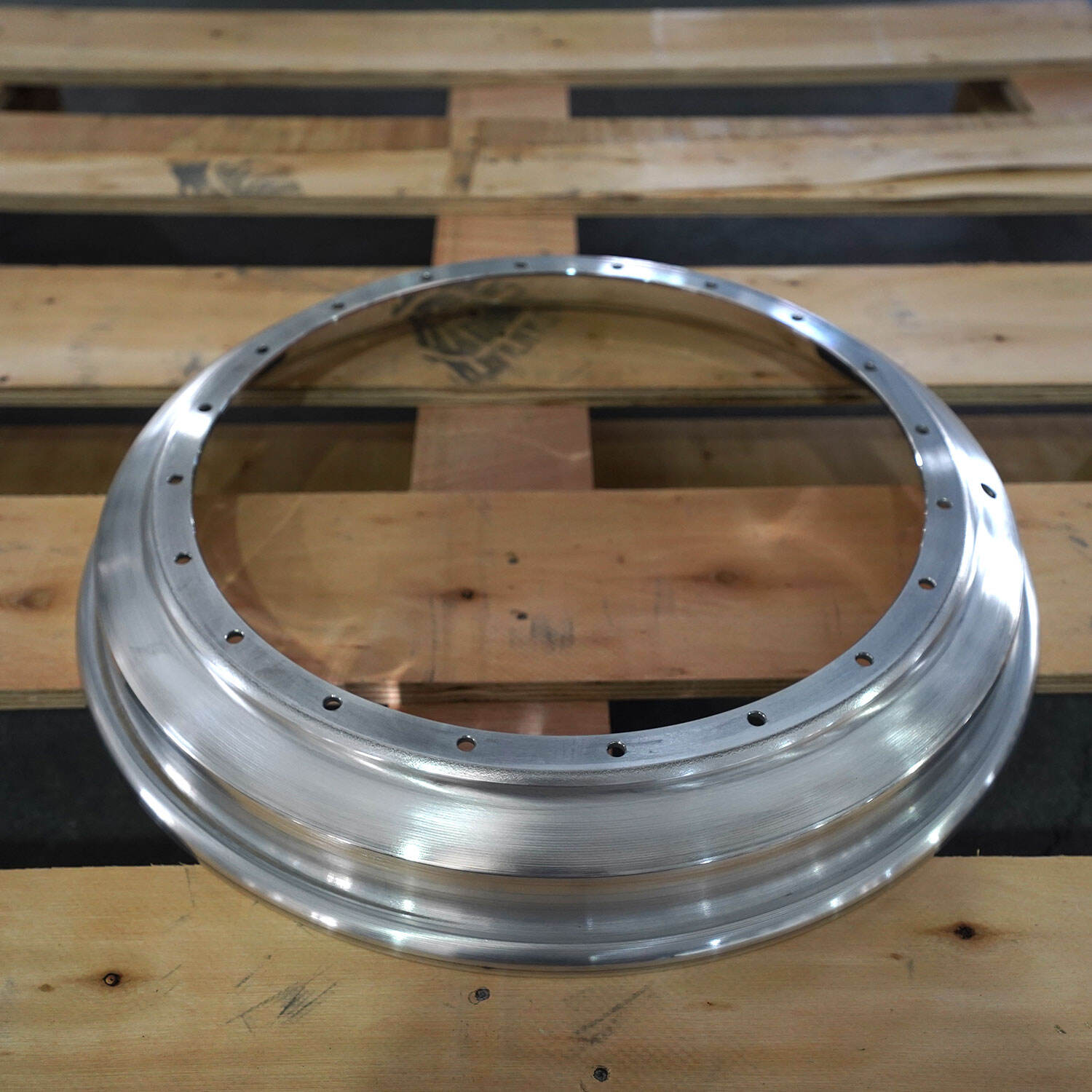

A three piece forged wheel hub refers to a forged wheel hub composed of three components: outer lip, inner barrel, and spoke.

They are fixed to the wheels by screws. The advantages of this type of wheel rim are light weight, good stability, and strong durability. Compared to traditional two-piece wheels, the strength of three piece wheels has increased by more than 30% and can withstand larger loads.

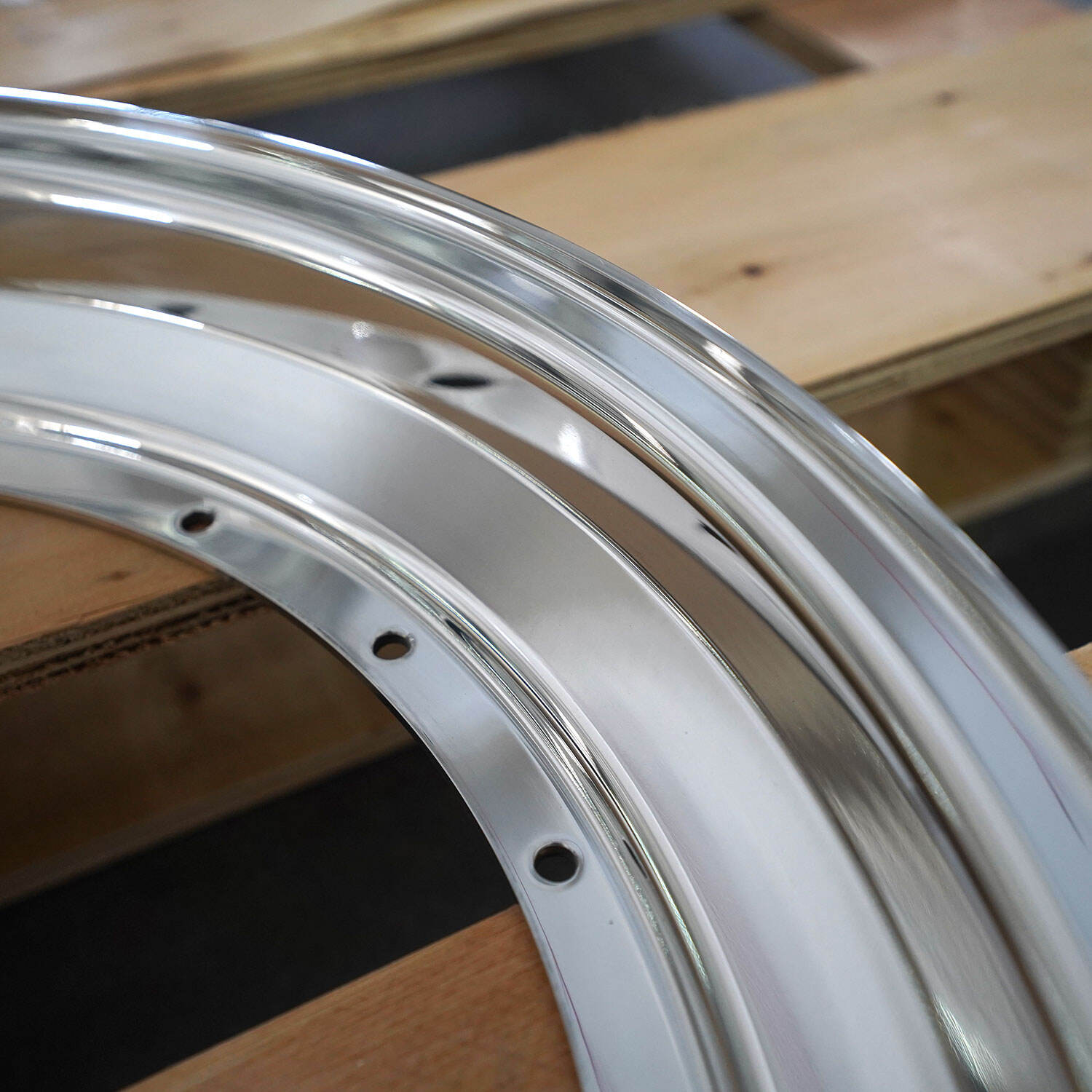

6061 T6 aluminum alloy plate is the main material for making wheels, which requires multiple steps such as shearing, spinning, quenching, turning, and punching to be processed, making it a very complex process.

Firstly, we need to cut the aluminum alloy plate into the desired shape, and then use a spinning machine to spin it into a fixed shape. In order to improve the integrity and stability of the wheel rim, it is necessary to place the wheel rim in a high-temperature box for quenching. After cooling, it is placed in a CNC turning machine to remove excess parts, so that the thickness of the wheel rim reaches a unified standard and further improves stability. Next, we need to use a drill bit to drill screw holes in the wheel rim steel.

Finally, we need to perform surface treatment to enhance the aesthetics of the wheels. We can use processes such as polishing, wire drawing, electroplating, or painting to complete this process.

Applications:

Fix the inner and outer wheels and spokes together with screws, apply sealant, and form a three piece forged wheel hub

Quick Detail:

Forged rim,outer lip,wheel lip,step lip,reverse mount,inner barrel,

Wheel barrel,3 pieces forged rim halves,2 pieces forged rim halves

3 piece forged wheel lip

Used for two-piece/three piece forged wheel hub modification, changing wheel hub styles, modifying large-sized wheels, and repairing accessories

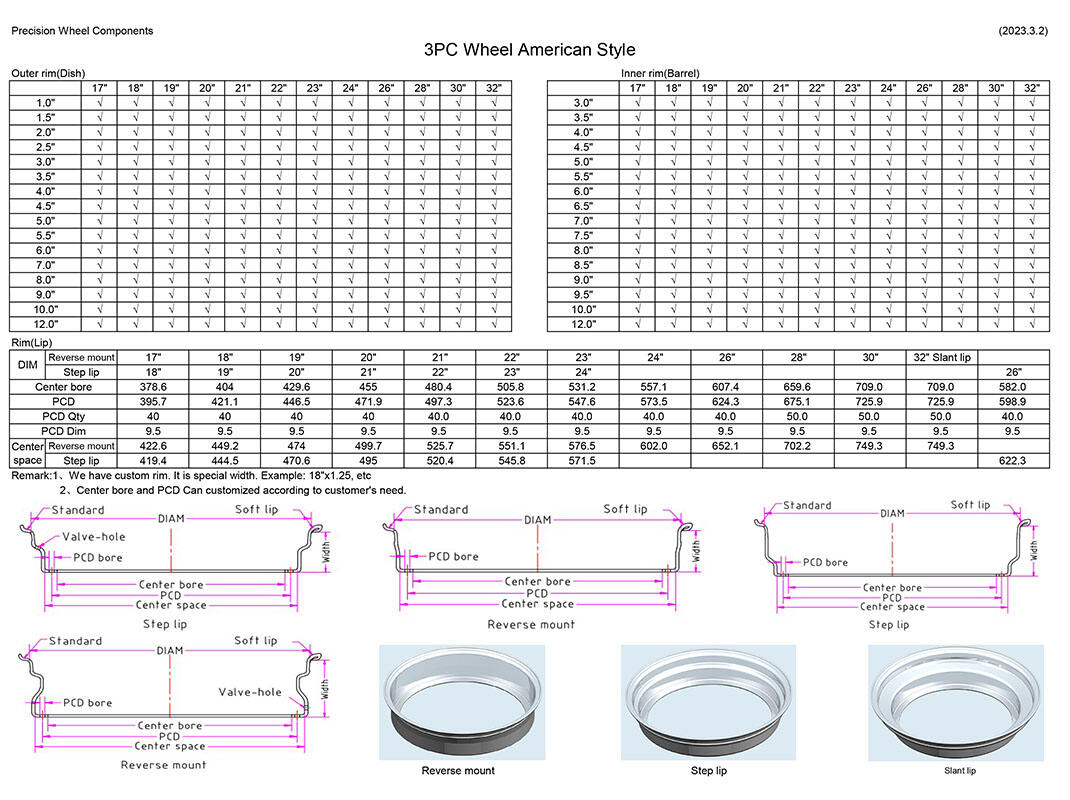

12 "to 32"

Specifications:

Competitive Advantage:

1. The wheel rim size ranges from 12 "to 32", with a wide range of sizes and complete wheel rim styles

2. Years of experience in foreign trade exports, providing one-stop solutions for customers

3. Multi piece forged wheels can manufacture wheels with unique shapes and exquisite appearances

4. Its three piece design and other configurations provide almost unlimited flexibility in diameter, rim width, and wheel offset to adapt to vehicle applications that cannot be achieved by other manufacturing methods.

| Minimum Order Quantity: | 1 |

| Price: | 92USD |

| Packaging Details: | Foam and Carton |

| Delivery Time: | In stock 15day,out of stock 30 day |

| Payment Terms: | TT |

| Supply Ability: | 5000/per month |

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

FA

FA

MS

MS

KK

KK